Sustainable safety solutions

Our society is unsustainable. Developed countries are overconsuming and over-exploiting the Earth's capacity by a factor of 1.75 on a global scale. The challenges are clear, but change is slow and limited. At Boplan, we know it's time to act. While we don't have all the answers yet, we believe it's better to start, learn and improve than not to start at all.

MAKE

Recycled materials limit the use of virgin materials and reduce the carbon footprint.

To ensure that our products meet all technical specifications and are free of hazardous chemicals, we recycle only our own post-industrial waste. This closed-loop recycling ensures that all input materials are 100% chemically identical to our virgin materials. We recycle 89% of our post-industrial waste, which means a yearly reduction of 344 ton CO2 compared to using virgin material.

MAINTAIN

The longer a product lasts, the less impact it has during over its lifetime.

Our polymer properties and product design allow our products to absorb impact without damaging themselves or your vehicles. As long as the design parameters are followed, the life expectancy of our products will easily exceed the time you need them. This not only saves money, but also prevents additional CO2 emissions and material usage.

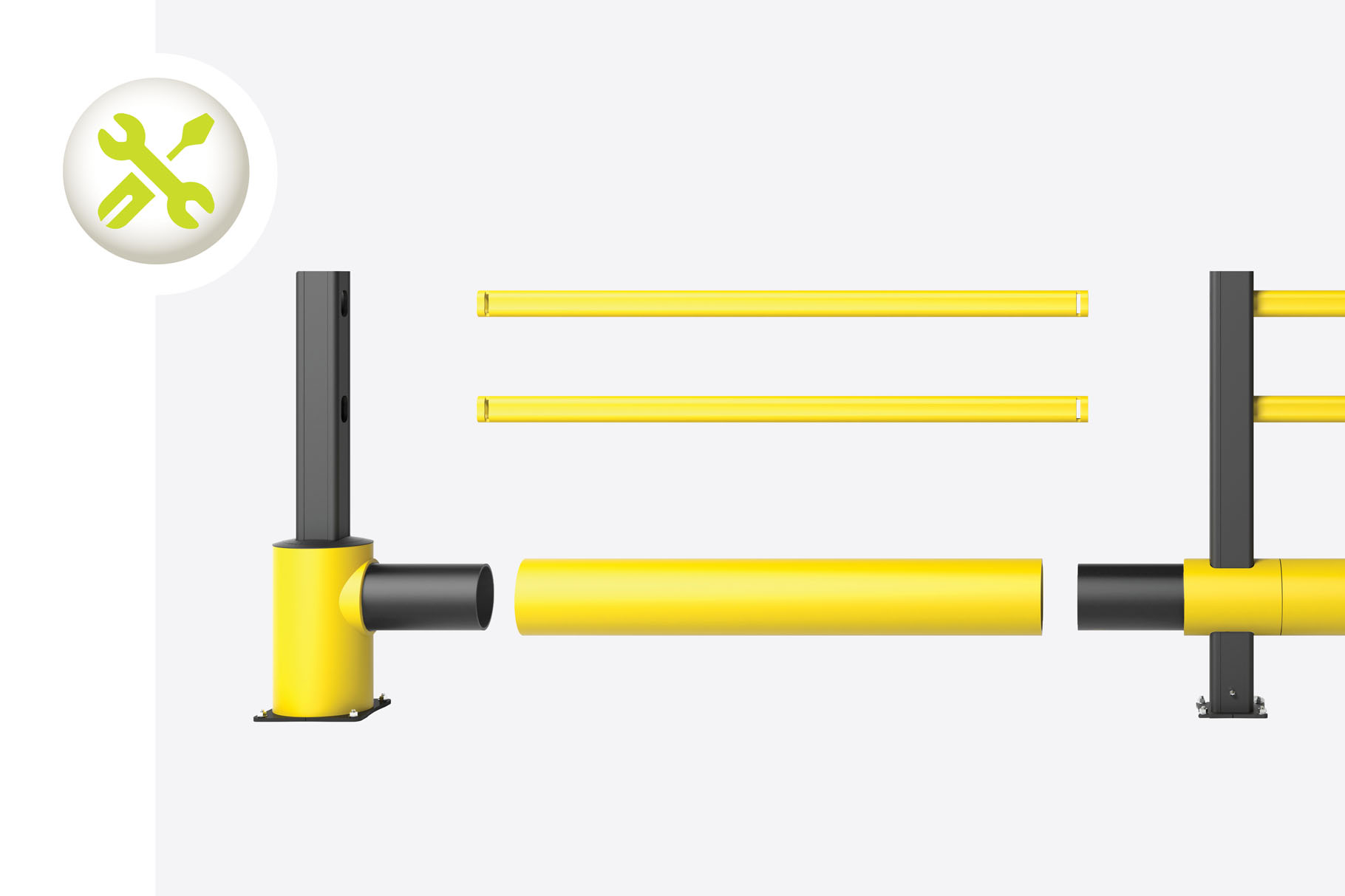

REPAIR

Repair options avoid unnecessary replacement of the entire product.

If the design parameters are exceeded, the product may be damaged. However, this doesn't mean that the entire product has to be replaced. The modular design of our product allows only the damaged components to be replaced and the other parts reused, again reducing material usage and carbon emissions.

We believe it's better to start, learn and improve than not to start at all.

Recycle

Recycling keeps resources in the material cycle and avoids waste.

Recycling requires the use of materials with proven, economically viable recycling pathways and a product design that allows for easy disassembly into single-material recyclable streams. Our products can be disassembled without special equipment, and up to 95% of their weight can be sent to existing recycling streams.

Take-back

Take-back programs ensure high-value remanufacturing or recycling.

Take-back programmes stimulate the circular economy because the manufacturer is best informed about how its products can be remanufactured or recycled. In anticipation of our standardised take-back programme, we are ready to evaluate take-back options upon request.

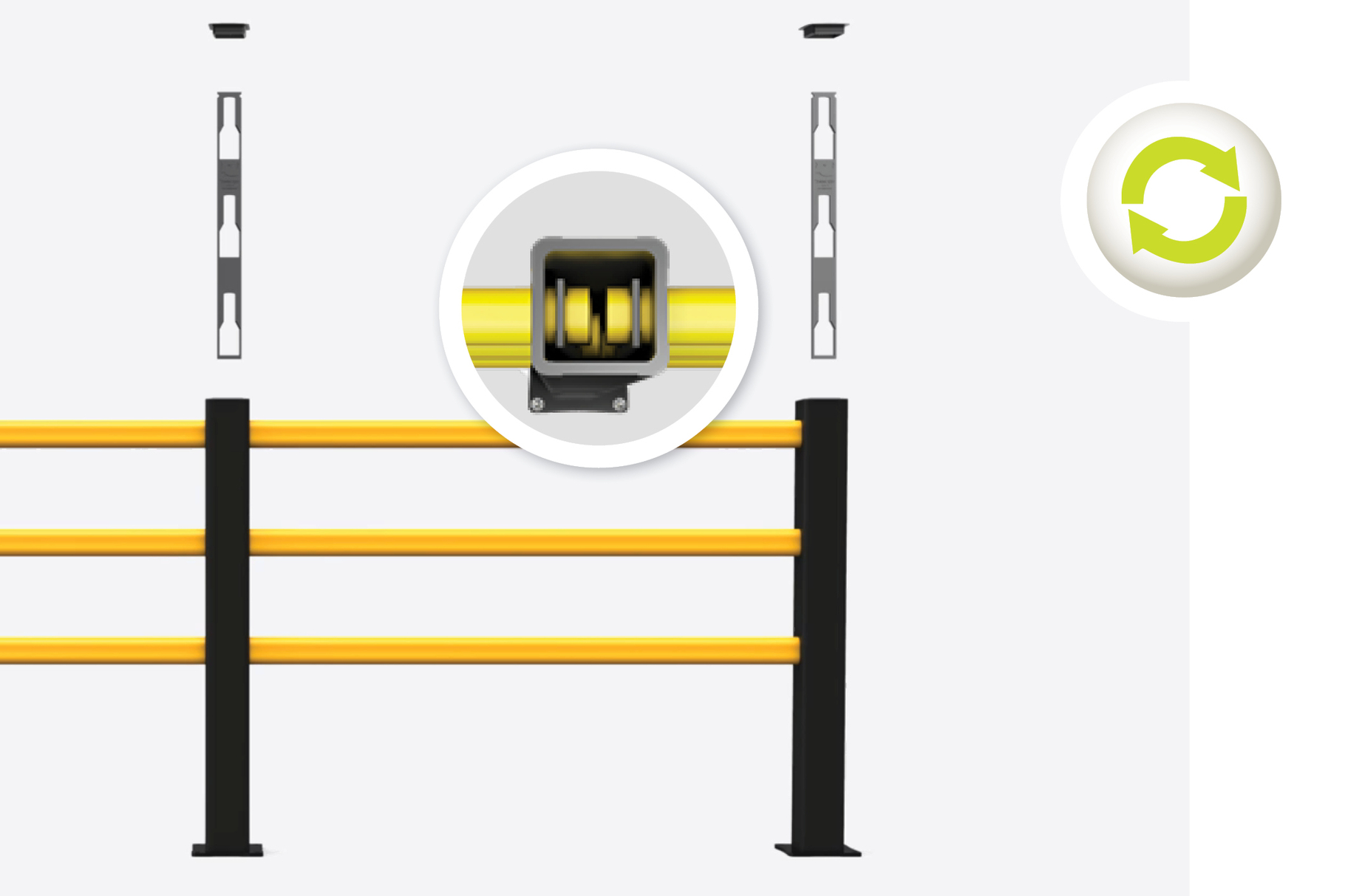

Reuse

Reusing a product reduces its impact.

Production facilities, warehouses, ... must adapt to changing business needs. We have designed our products to be easily disassembled and reassembled so you can reuse them. This modular design also allows for modifications (e.g., change in length) to maximize reuse opportunities.

Are you interested in learning more about our efforts, do you have questions or do you want to share your opinion, don't hesitate to contact our Sustainability Project Manager via sustainability@boplan.com

Choose cost-competitive circular alternatives

You're in control

A company’s carbon footprint goes beyond its energy use. Every business needs raw materials, supporting products and services, transport and so on. All of these things come with their own CO2 backpack. These so-called Scope 3 emissions can amount to 10 times the CO2 emissions associated with energy use. And because you're in charge of these aspects, you’re in control.

Choosing circular products will help reduce your company's Scope 3 emissions, and probably at no extra cost: cost-competitive circular alternatives are usually available. In fact, you'll almost always be better off when you consider the total cost of ownership, taking into account the lower replacement and disposal costs.