Tested and approved according to the highest safety standards

Your safety is our top priority. Therefore, we extensively test all new Boplan safety products before they hit the market. External and independent parties test the absorption capacity, strength, and quality. This ensures that our products meet the highest safety standards.

A HOUSE OF INNOVATION

Boplan R&D

Boplan R&D is not your typical research and development team. It consists of two complementary teams that constantly challenge and inspire each other to create exceptional products. Our Innovation Team is the creative force behind our success. It is responsible for designing and redesigning products. It introduces innovations and works directly with the sales department. Meanwhile, our Research, Engineering & Development (RED) Team is responsible for technical validation, managing intellectual property, and overseeing certification and testing processes.

At Boplan R&D, innovation knows no limits. We are rewriting the rules and shaping a future where the possibilities are endless.

THE BEST OF TWO WORLDS

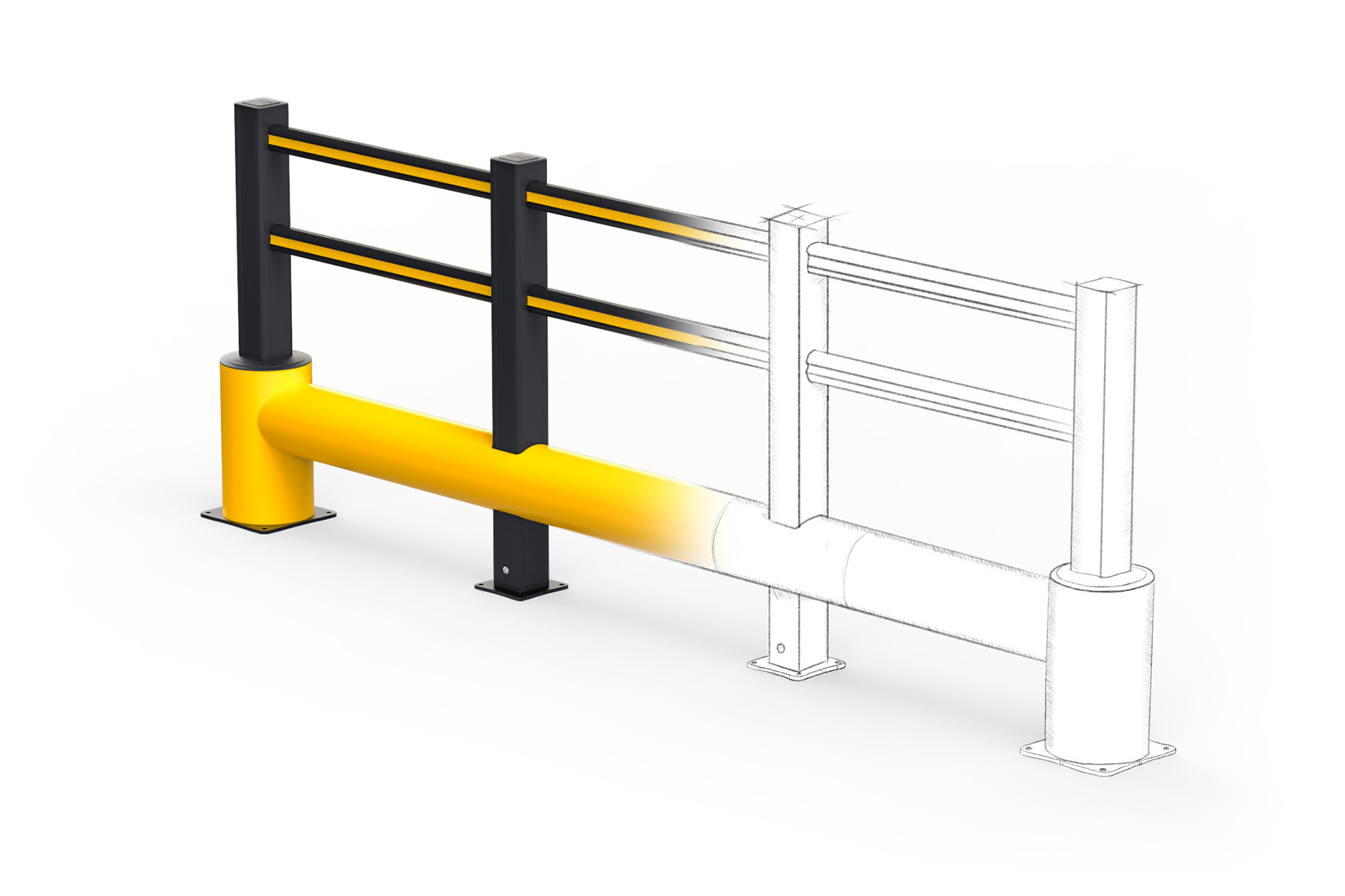

TECHNICAL PERFORMANCE AND APPEALING DESIGN

We believe that safety doesn't have to be boring or unattractive. When it comes to design, we pay particular attention to the functional aesthetics of our safety products. While others may consider it an afterthought, at Boplan we strive to enhance the visual appeal of your workplace.

OUR INNOVATION PROCESS

FROM CREATIVE IDEA TO INSTALLATION

Our ideas are business-driven, market-driven, or fit into our IP strategy. A selection of ideas is further developed with sketches, renderings ... If an idea has real potential, we draw up a project charter to turn it into an R&D project and start building prototypes and testing them functionally. This concept phase is followed by the engineering phase. Here we work towards technical validation based on:

Feasibility testing

internal and external accredited

laboratories (according to ISO17025)

Production testing

with internal virtual and real-life simulations

and vehicle impact tests according to

PAS13:2017 & UNI/TS 11886-1

Industrial testing

to ensure process stability and quality

*Testing is carried out under third-party supervision (TÜV Nord) and is recognised with product certificates.

Testing at Boplan

WHERE INNOVATION MEETS PRECISION

Our in-house testing facilities play a crucial role in driving continuous innovation and improvement. By replicating real-life scenarios and rigorously evaluating the performance of our safety products, we ensure the highest levels of reliability and effectiveness in your facility.

Indoor Test Lab

Our indoor test lab is a testament to our commitment to excellence. Here, we can test at any time, regardless of weather conditions or external factors. This controlled environment allows us to create repeatable conditions, ensuring precise and accurate results. We meticulously recreate scenarios, from varying floor conditions to impact angles, that our safety products may encounter in reality.

ADVANCED DATA COLLECTION

Our test facilities are equipped with the latest technology, including on-board computers, lasers, and high-speed cameras. These advanced data collection systems capture precise information that gives us invaluable insight into the performance of our safety solutions. It allows us to measure and analyse key metrics with utmost precision, ensuring that every product leaving our factory meets the highest safety standards.

IMPACT PROTECTION

MARKET LEADER AND CONSULTANT IN SAFETY STANDARDS

Our experience in crash testing has enabled us to develop specialised software that predicts, through simulations, the behaviour, load, impact, deflection, and stress for each of our products. To incorporate all this knowledge into our products, we work closely with renowned research companies and university research centres. Because of our expertise, we have been called upon as consultants to help establish safety standards in our industry.